PCB Solution

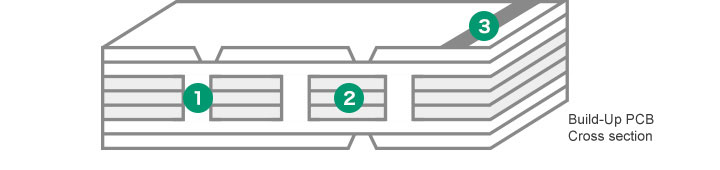

In response to an increasing need for electronic device and oarts that are more deverse and sophisticated, printed circuit boards (PCBs)are of key inpotancein meeting such needs. Along with the move to higher board densities, more layers and smaller holes, fabrication methods and mounitng tehnology is undergoing major changes.

As the industry leaders, Via mechanics has been quick to respond to such needs through its PCB Drilling Machines and has used the technologies involved as a basis for a broad range of research and development, resulting in equipment for PCB fafbrication such as Laser processing machines that continue to define the leading edge in electronic parts

manufacturing systems.

In addition to providing such machines, we provide total PCB solutions that cover every aspect

of PCB fabrication. These solutions have an excellent reputation and have brought us a high level of customer confidence.

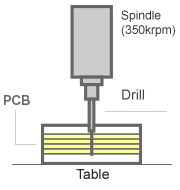

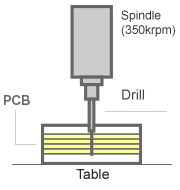

- ① Mechanical Drilling

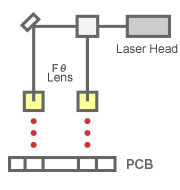

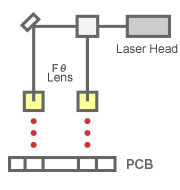

- ② Laser Drilling

- -Through-hole Drilling

(TH、Through Hole)

Hole Diameter:0.050~6.35mm・Ultra High speed Spindle

・High Precision Servo system Micro drilling of hole diameter 50μm achieved with ultra high speed spindle (max. 350,000rpm/min.)

Micro drilling of hole diameter 50μm achieved with ultra high speed spindle (max. 350,000rpm/min.) High precison positioning of smaller hole drilling. Achieved Process Precision of ±15μm

- -Blind-hole / Micro through-hole Drilling

(BH,Blind Hole)

Hole Diameter:0.030~0.35mm・High Speed and High Precision Galvano systemHigh speed positioning with the unique Galvano scaner (Max 3,500Hz.)

・Multi panel, laser beam and laser source application Our unique 1/2/4 panel and laser beam applications.Applicable for smaller-hole, any layer PCB processing with CO2 and YagUV Laser source.

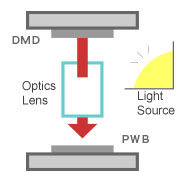

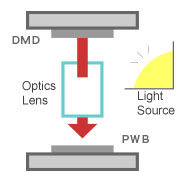

Our unique 1/2/4 panel and laser beam applications.Applicable for smaller-hole, any layer PCB processing with CO2 and YagUV Laser source. - -Patterning

Line / Space:min.8μm・Small and high prexision optical system

・High speed data processing Our unique optical systems improved for the finer patterning. Achieved more minute beam spot diameter.

Our unique optical systems improved for the finer patterning. Achieved more minute beam spot diameter.2.2GB/sec data conversion achieved with Ultra High Speed Real-time Data Processor.

Micro drilling of hole diameter 50μm achieved with ultra high speed spindle (max. 350,000rpm/min.)

Micro drilling of hole diameter 50μm achieved with ultra high speed spindle (max. 350,000rpm/min.)

Our unique 1/2/4 panel and laser beam applications.Applicable for smaller-hole, any layer PCB processing with CO2 and YagUV Laser source.

Our unique 1/2/4 panel and laser beam applications.Applicable for smaller-hole, any layer PCB processing with CO2 and YagUV Laser source.

Our unique optical systems improved for the finer patterning. Achieved more minute beam spot diameter.

Our unique optical systems improved for the finer patterning. Achieved more minute beam spot diameter.